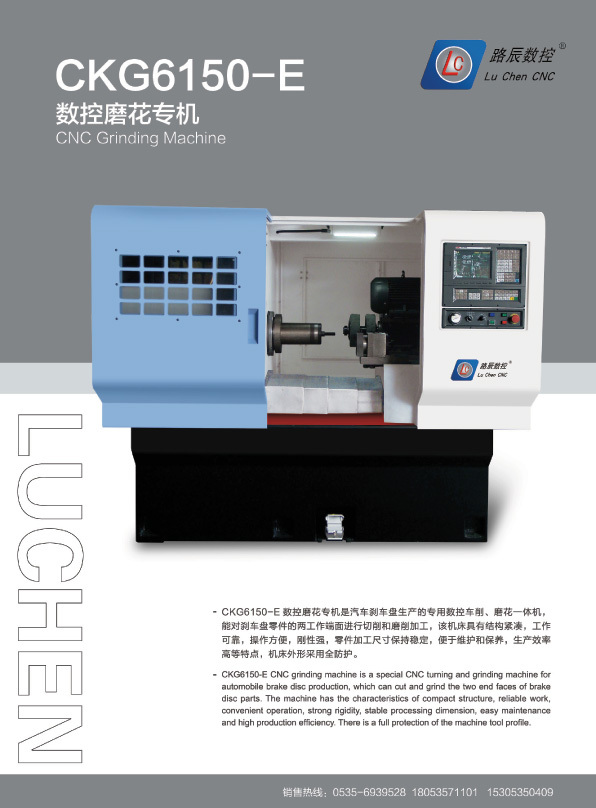

CKG6150-E CNC Grinding Machine

The CKG6150-E CNC grinding machine is a type of precision machinery used for grinding operations, typically in manufacturing and machining environments.

Key words:

Product Classification:

Product Details

The CKG6150-E CNC grinding machine is a type of precision machinery used for grinding operations, typically in manufacturing and machining environments. Here are some general features and specifications that may be associated with this type of CNC grinding machine:

Key Features:

1. **CNC Control System**: Equipped with a computer numerical control (CNC) system for precise automation and programming of grinding operations.

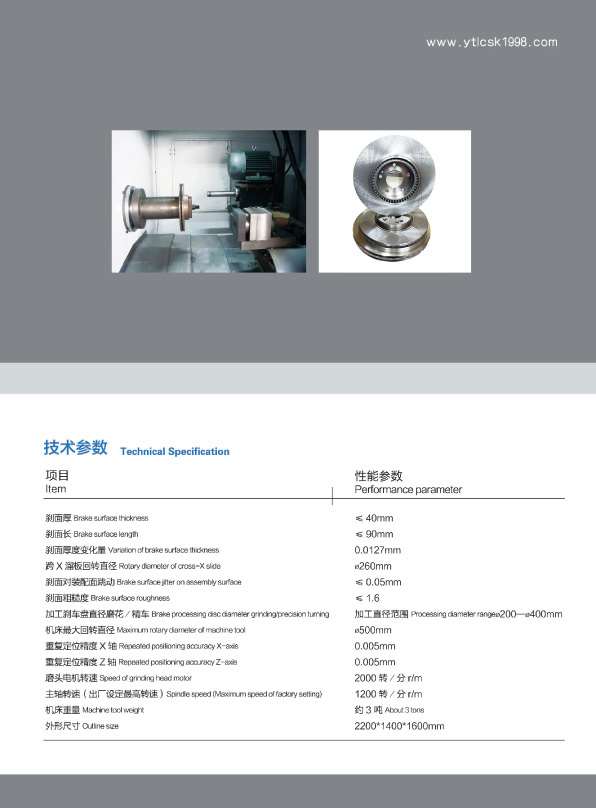

2. **High Precision**: Designed to achieve high accuracy and repeatability, essential for producing parts with tight tolerances.

3. **Grinding Wheel**: Typically comes with various grinding wheel options to accommodate different materials and applications.

4. **Multi-Axis Capability**: Many CNC grinding machines, including the CKG6150-E, may feature multi-axis movement (e.g., X, Y, Z axes) for complex part geometries.

5. **User-Friendly Interface**: Often includes a user-friendly control panel with a graphical interface for easy programming and operation.

6. **Automatic Tool Change**: Some models may have an automatic tool changer to facilitate different grinding tasks without manual intervention.

7. **Cooling System**: A built-in cooling system to manage heat during grinding operations, which helps maintain the integrity of both the tool and the workpiece.

8. **Safety Features**: Equipped with various safety features to protect operators and the machine itself during operation.

Specifications (Hypothetical):

- **Max Grinding Length**: 1500 mm

- **Max Grinding Diameter**: 300 mm

- **Spindle Speed**: 3000-6000 RPM

- **Motor Power**: 5-10 kW

- **Weight**: Approximately 2000 kg

- **Dimensions**: Varies based on configuration

Applications:

- Precision machining of components in industries such as aerospace, automotive, and manufacturing.

- Grinding of shafts, gears, and other intricate parts.

- Tool and die making.

Maintenance:

Regular maintenance is crucial for CNC grinding machines to ensure longevity and performance. This includes:

- Routine cleaning of the machine.

- Lubrication of moving parts.

- Inspection and replacement of grinding wheels.

- Calibration and software updates for the CNC system.

Conclusion:

The CKG6150-E CNC grinding machine represents a significant investment in precision manufacturing capabilities. It is important to refer to the manufacturer's specifications and user manuals for detailed operational guidance and maintenance schedules specific to the model. If you have specific questions about the machine or need more detailed information, please let me know!

Related Products

ONLINE MESSAGE

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible.